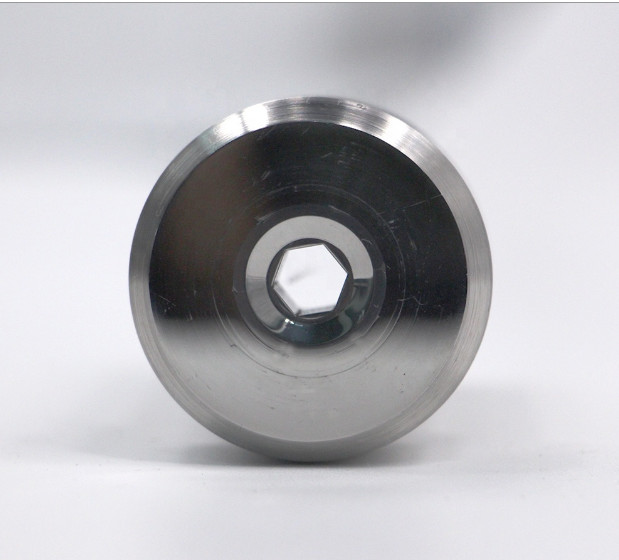

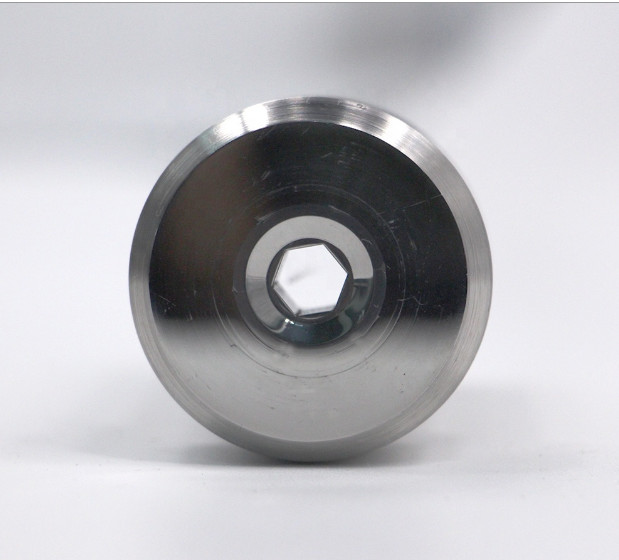

Production Description

Carbide molds are an excellent choice for manufacturing ferrous

metal rod size wires. They are also ideal for short-term trial

runs. JWE TC wire drawing die adopts mirror polishing and smooth

wire entry to ensure the best die life and wire drawing. JWE

provides a complete series of TC wire drawing dies, suitable for

rod size wire to medium size wire.

Features:

Faster speed: Due to the high thermal performance of the nozzle in

general, the printing speed can be pushed even further without

sacrificing the quality. The special shape inside the nozzle — made

possible by Dyze Design’s machining and manufacturing techniques —

improves the flow where the diameter tapers, thus allowing a faster

flow rate.

Low friction: The whole nozzle is electroless nickel plated for

enhanced slippery properties. Plastic will slide on the nozzle

instead of sticking to it. This results in cleaner parts and fewer

issues from drag.

Unbeatable price/performance: Tungsten carbide is easier to produce

than corundum (Sapphire, Ruby, etc) while the performance is very

similar for abrasion and much more performant for thermal

conductivity. The use of steel makes it very easy to manufacture

and offers amazing thermal performance. In all the whole package is

a win-win situation in terms of performance and price.

Advantage

- Suitable for black metal rod size wire

- Suitable for short-term and trial operation

- Carbide grade customized for wire when necessary

- Special coatings that can be used to reduce friction and/or enhance

durability

- Provide inventory plan

Application

▪ tungsten carbide die

▪ Natural diamond wire cutting

▪ Single crystal diamond mold

▪ PCD drawing die

▪ High crystalline diamond wire drawing die

Grades and Properties

| Grade | Density(g/cm3) | Hardness(HRA) | TRS(MPa) |

| YG6X | 14.95 | 91.5 | 1800 |

| YG6 | 14.95 | 90.5 | 1900 |

| YG8 | 14.8 | 89.5 | 2200 |

| YG10 | 14.5 | 88.5 | 2400 |

| YG15 | 14.0 | 87.0 | 2800 |

Performance Chart

Product Packaging

Company Introduction

JWE Carbide Co., Ltd. is designated as a high-tech and new material

enterprise was founded in March of 2005, with a registered capital

of USD1, 000, 000, located in Lukou Economic Zone of Zhuzhou city,

the hometown of Chinese Tungsten Carbide. Our factory covers an area of 20,000 square meters, equipped with

advanced technologies and manufacturing equipment, we major in

researching, developing, and producing medium and high-grade

tungsten carbide products.

FAQ

Q: Are you a trading company or manufacturer?

A: We are a professional factory for 15 years.

Q: Trade Assurance?

A: We have joined the Trade Assurance on Alibaba to protect your

payment to make sure that we deliver on time and manufacture

quality products as required.

Q: How to send an inquiry?

A: It's better to send us detailed specifications of products, it's

better attaching some photos for better understanding, You

can:-Send us an inquiry from the Alibaba.com platform.-Send email

to us directly, salespersons always wait for service at work.

Q: How do you guarantee your quality?

Firstly, we do a quality test during every process. And we use

production instruction cards when one process finished, the work

will be signed on the production instruction cards. Secondly, we

will collect all comments on our products from customers in time.

And try our best to improving quality all the time.

Q: Do you offer samples?

A: Yes, we do offer samples. However, buyers need to pay for the

freight charge. In addition, whether samples are free or not

depends on the quantity you buy.

Q: What kinds of payment do you accept?

A: In addition to the patterns of payment shown above, you can

discuss with us in which way you would like to pay.